ACID CONTAMINATION

Over the last years, the copper technology has incorporated sodium chloride to the extraction process, to increase the extraction efficiency of the metal, which becomes part of the PLS that reaches the SX Plant. Part of the sodium chloride is not removed in the SX Plant and joins the electrolyte in the electrowinning process. The electrolyte is rich in sulfuric acid and the reaction between sulfuric acid and sodium chloride forms hydrochloric acid as shown below:

As the content of sulfuric acid in the electrolyte is high, the equilibrium of the reaction moves to the right and much of the chloride is found as hydrochloric acid, whose boiling point is 48°C. As the electrolyte temperature is 50°C, most of the acid contamination comes from the hydrochloric acid issued during the process. This affects heavily the stainless-steel elements inside the bay, causing corrosion under the bolts, as well as undermining and pitting in piping supports and stands. The chloride contained in the electrolyte can also react with copper sulfate to form: yellowish-green color cupric chloride which, when hydrated turns into a greenish-blue; and/or a red color copper chlorinated compound. Both products can be entrained into the environment by the hydrochloric acid. The reactions are as follows:

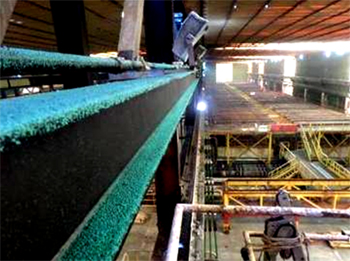

Blue-green copper salts due to high hydrochloric acid contamination

This situation should be considered when projecting these types of Plants and the antacid systems must be designed according to this new agent, which is highly aggressive and destructive.