SERVICE

DESIGN

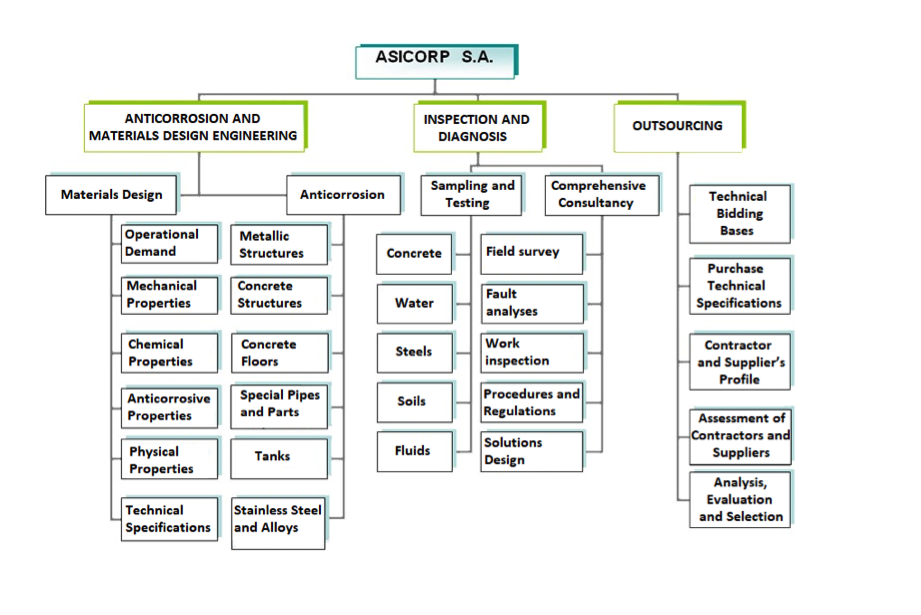

Design of Materials and Anticorrosive Technologies

The design and selection of materials is another service, considers the research, specification and applicability of these in a technical solution through knowledge of their properties. It is based on the analysis of its attributes and limitations regarding the physical, chemical, mechanical and operational requirements to which it will be subjected.

ANALYSIS

Fault analysis, inspection, sampling and testing

The services in this area include mainly fault analyses, evaluation of the type, degree and progress of corrosion in metal and concrete structures, diagnosis of the state of the coatings, inspection and quality control of the paint job, monitoring and permanent field advice on work and manufacturing activities, whether for new projects or maintenance work. The quality and work methodology is based in the application of norms and standards established according to each project, consider the general and detailed analysis of a task and the approach of solutions that allow the achievement of the final objective with optimal results and in a safe condition.

OUTSOURCING SERVICES

The outsourcing consists of providing support to the procurement departments, in terms of searching and assessing contractors, materials, products and suppliers, for a specific project or requirement. It is a study and analysis that determines those companies that are trained and meet the requirements to supply a product or service according to the requirements of the project.

This service area corresponds to the evaluation, study and design of corrosion protection systems for all types of installation, using the technologies offered by the market. These technologies are studied, analyzed and specified according to each substrate, operative condition and feasibility of application of the product.

To fulfill the purpose of designing a technical solution to ensure the best corrosion control, the anticorrosive demand of the area and system to be protected must be evaluated, in such a way that the anticorrosive design meets that demand.

Economic analyses of losses due to corrosion performed in different countries report a figure that ranges between 3% and 6% of the GDP. Other studies indicate that 25% of the world’s steel production is lost due to corrosion. These very high indexes can be controlled and reduced significantly, by incorporating the anticorrosive perspective into the projects as required. This is even more relevant in maintenance projects, which are usually carried out without the analysis and prior study of the operational situation or the anticorrosive demand, which are the basic parameters for the exact definition of the problem. By ignoring these aspects, both, the work planning and the proper selection of products become a highly sensitive and complex issue to manage. The contractor begins to perform his work unaware of the operation and related interference, which generates unforeseen events, changes in the planning, production losses, loss of profit, longer deadlines and extensions of the contract.

The technical and economic success and the right timing of these projects is based on the drafting of adequate technical bidding bases, studied and prepared according to the sector, environment and type of operation of the area to be intervened.

EXPERT ANALYSES

It includes steel and concrete substrates for all types of installation, regardless of the corrosive environment. This service covers the following:

1.-Fault analysis:

Corresponds to cases of structural collapse due to damage caused by corrosion. It is a thorough field inspection and a detailed evaluation of the root causes of the problem. The report describes the cause of the damage, the progression of the damage and the technical solution to repair the problem.

2.-Corrosion Diagnosis analysis:

Corresponds to a survey of the corrosion status of a facility, the most critical situations, priorities for maintenance, analysis of interferences and technical solutions for the whole area and for each sector in the case of micro-environments.

EXPERT INSPECTIONS.

This service covers inspection and quality assurance of coating applications, monitoring and permanent on field advice on the activities in a construction or manufacturing facility, whether for new projects or maintenance. The working methodology of this service is based on the implementation of quality standards, according to the requirements of each project, considering the analysis of complex situations during the work and our proposal of technical solutions to maintain the required quality standard.